Products

The Energy Saving Device for Elevator

Key words:

Classification:

The Energy Saving Device for Elevator

- Product Details

-

- Commodity name: The Energy Saving Device for Elevator

- Commodity ID: 03

- 副标题副标题: Устройство для экономии энергии в лифте Dispositivo de ahorro de energía جهاز توفير الطاقة للمصعد Asansör enerji tasarruf cihazı Perangkat penghemat energi lift

○ National key product in new plan Reported by CCTV repeatedly ○ Used in the ministry of science and technology, the general hospital of China PLA and other more than 1000 energy saving program in countrywide

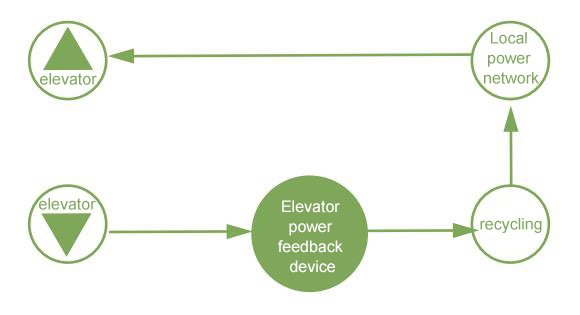

System Overview

The electric energy feedback device of the prospect photoelectric elevator is to invert the electric energy generated by the elevator traction machine under the condition of unbalanced load, and the inverter becomes the same frequency and phase alternating current with the power grid and returns it to the local power grid. For the use of elevator main board, elevator shaft, car lighting, car fan, etc. and nearby places with load (or other elevators and auxiliary equipment).

The electric energy generated by the traction machine power generation process needs to be handled in time, otherwise it will cause serious harm to the traction machine. The conventional variable frequency elevator to deal with this part of the electric energy is to install a braking unit and a braking resistor at the DC capacitor end. When the voltage at both ends of the capacitor reaches a certain value, the braking unit will operate, and the excess electric energy will be converted into heat energy through the braking resistor and dissipated into the air.

The electric energy feedback device replaces the brake unit and the brake resistor. By automatically detecting the DC bus voltage of the inverter, the DC link of the inverter is inverted into AC power with the same frequency and phase with the power grid, and is connected to the AC power grid after multiple noise filtering links, so as to achieve the purpose of green, environmental protection and energy saving.

Technical indicators

Braking mode Bidirectional automatic voltage tracking mode Braking response time < 2ms Inverter input voltage AC150V ~ 460V,45 ~ 66HZ Applicable power 0 ~ 30kW Input operating voltage DC270 ~ 780V (adjustable), error 2V Output mode sine wave current mode current distortion <5% Braking torque 150% Design work system Long term Protection Overheat, Overcurrent, Overvoltage, Phase loss Ambient temperature -10°C ~ 60°C Good ventilation Atmospheric pressure 86kPa ~ 106kPa Relative humidity <90% RH (no condensation) Vibration 1g(10~20Hz),0.2g(20~50Hz) Protection level IP00 Appearance size 390mm × 340mm × 200mm DC5V power output <150mA System features

① High-precision inverter module

• The original imported IGBT module is selected, and its module adopts CSTBT silicon chip technology, with low saturation voltage drop and high short circuit tolerance. The temperature sensor is set on the silicon chip to make the over-temperature protection more accurate;

Advanced processor and feedback algorithm

• Using DSP central processing unit and small harmonic SVPWM feedback algorithm, high speed, high precision, high stability, strong anti-interference, effectively improve the energy conversion rate of the whole system, avoid the generation of high harmonics;

③ to adapt to a wide range of simple installation

• Product adaptability, AC380V and AC200V elevator can be a common product, the installation of DC bus is positive and negative, simple and fast;

④ Good heat dissipation and high quality feedback quality

• The radiator with large volume and excellent materials has good heat dissipation effect, so that the heat generated by the elevator electric energy feedback device can be dissipated in time and quickly, and the conversion efficiency of the product is above 97%. The material of high-power reactor has the characteristics of high saturation magnetic induction, high initial permeability and low high-frequency loss, and the main component is amorphous and nanocrystalline soft magnetic alloy to ensure the quality of power feedback;

⑤ Self-diagnosis and protection

• The use of fault self-diagnosis and protection output technology ensures the accuracy of the output voltage, effectively prevents the current from returning, and ensures the safe operation of the inverter;

Anti-island effect

• The device integrates anti-islanding detection technology to ensure the safety of the entire circuit system and debugging and maintenance personnel;

⑦ Excellent component quality

• All core devices are imported components, using advanced production technology to ensure product performance and product quality;

⑧ Advanced Testing Facilities

• Have a domestic electric energy feedback device testing platform;

Multiple protection functions

• The feedback device is connected in parallel with the brake unit, which has the function of automatic fault diagnosis and protection, and realizes the detection of multiple protections such as phase loss, disconnection, overvoltage, overcurrent, and overheating.

Wiring Diagram

Why is it generating electricity?

The elevator with variable frequency speed regulation has greater mechanical energy after starting and running at a higher operating speed. The elevator must gradually decelerate until it stops moving before reaching the target floor. This process is the process of releasing mechanical kinetic energy of the elevator traction machine.

The elevator is also a potential energy load. In order to drag the load evenly, the load dragged by the elevator traction machine consists of the passenger car and the counterweight balance block. Only when the car load is about 50% (about 7 passengers per ton of passenger elevator), the car and the counterweight balance block are balanced with each other. Otherwise, the car and counterweight will have poor quality. Make the elevator run to produce mechanical potential energy (elevator heavy load down and light load up).

The excess mechanical energy (including potential energy and kinetic energy) in the operation of the elevator is converted into DC electric energy through the action of the traction machine and the frequency converter and stored in the capacitor in the DC circuit of the frequency converter. At this time, the capacitor is like a reservoir. The more electric energy is returned to the capacitor, the higher the capacitor voltage (like the reservoir, the water level is too high). If the electric energy stored in the capacitor is not released in time, overvoltage fault will occur, causing the frequency converter to stop working and the elevator cannot operate normally. At present, the vast majority of domestic variable frequency speed control elevators use the method of storing electric energy in the resistance consumption capacitor to prevent the capacitor overvoltage. But resistance energy dissipation not only reduces the efficiency of the system. At the same time, the large amount of heat generated by the resistance also worsens the environment around the elevator control cabinet, and the emergence of the elevator power feedback device solves this problem well.

The elevator electric energy feedback device can effectively return the electric energy stored in the capacitor to the regional AC power grid for use by other surrounding electrical equipment. The power saving effect is obvious, and the power saving rate is 45%. In addition, because there is no resistance heating element, the temperature of the computer room drops, which can save the power consumption of the air conditioner in the computer room. In many occasions, saving the power consumption of the air conditioner often brings a greater power saving effect.

Advantages of Elevator Standard

① The four-quadrant operation of the variable frequency speed control system is truly realized;

② The energy generated by braking is recycled and the efficiency of the system is greatly improved. The air conditioning and exhaust facilities for cooling in the elevator machine room can be closed for use;

The system heat is low, the safety and comfort of the elevator is improved, and the maintenance workload is reduced;

④ Improve the braking effect and adapt to the engineering requirements of rapid braking and frequent braking.

Product inquiry

Note: Please leave your E-mail and our professionals will contact you as soon as possible!

Cooperation cases

Industrial Bank of Quanzhou City, Fujian Province

Nanyang Seaview Hotel, Zhuhai City, Guangdong Province

Liaoning Technical Supervision Bureau

Jinan Municipal Government of Shandong Province

中文版

中文版 ENGLISH

ENGLISH